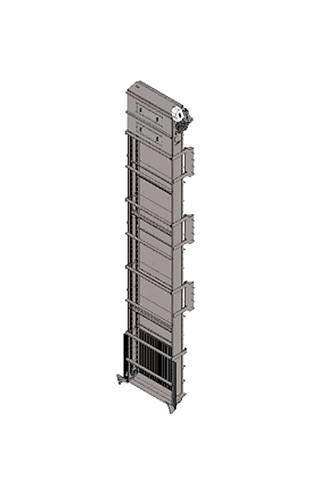

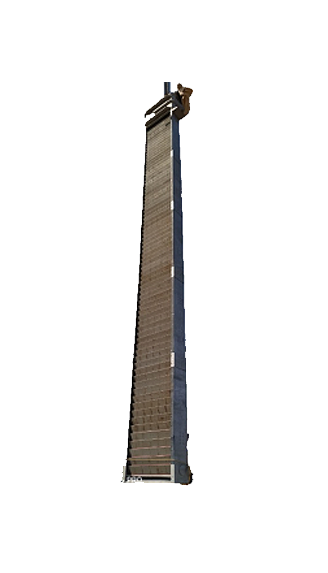

MANUAL BAR SCREENS

| SERIES: B111-1 – MANUAL BAR SCREENS | ||

|

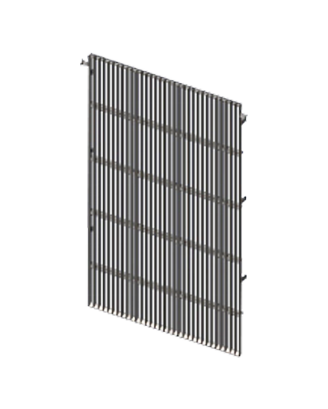

Manual bar screen with vertical flat bars spaced apart is used to prevent large and medium floating wastes from travelling further into the screening chamber. These are generally installed at the upstream of Mechanical bar screen as well as a standby to the mechanical bar screen. Cleaning of screen has to be done manually with the help of manual rake comb provided with the screen. Manual screen can be provided either as fixed type or removable type. | |

| Bar Spacing | 6 mm and above. | |

| Channel width | Maximum up to 3,000 mm. | |

| Channel depth | Maximum up to 5,000 mm. | |

| Mode of operation | Manual | |

| Material of Construction | Carbon Steel / Stainless Steel 304, 316 / Duplex / Super Duplex. Other material on request. | |

| Technical Features | Click to open | |

| Drawing & Data Sheet | Click to open | |